One solution for LSPs is to introduce battery-electric heavy-duty trucks (HDTs). However, this is rarely done today, due to the high investment costs of such trucks. To compensate these high investments, high mileages are required in order to benefit from such vehicles’ low operating costs.

Implementing 24-hour delivery would increase the daily mileage of HDTs. Because of noise emission regulations, 24-hour delivery could only be performed using battery-electric HDTs.

In a recent study, researchers from Fraunhofer Institute and the University of Hohenheim explored whether using battery-electric HDTs for 24-hour delivery is economical for LSPs.

The researchers used data from a German LSP in food logistics, develop a system dynamics model, and integrate a total cost of ownership calculation along with an LSP and a retail store discrete choice model to determine whether 24-hour delivery with battery-electric HDTs is profitable for the LSP, and how it might be accepted and diffused among stores.

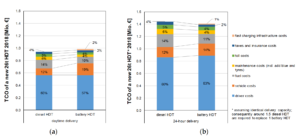

They found that 24-hour delivery using battery-electric HDTs is immediately profitable. This is due to the almost 50% increase in the daily trip potential of battery-electric HDTs in comparison to diesel HDTs, which leads to a lower required total number of HDTs in the fleet. Lower transportation costs, increased delivery quality, and decreased risk lead to the rapid adoption of 24-hour delivery among stores, while lower total costs of ownership (TCO) accelerate the adoption by the LSP.

Diffusion through the fleet and stores takes only slightly longer than one HDT lifetime. Consequently, 24-hour delivery with battery-electric HDTs is a promising solution for innovative and sustainable city logistics.

Source: