The eCARe project is a process-based charging management concept for e-car logistics that began in 2021. Until now, research for electromobility has focused on component development or the creation of charging infrastructure for end customers. However, with increasing sales of e-vehicles and global production, there is a need for optimized logistics that take into account the specific characteristics of battery or fuel cell vehicles.

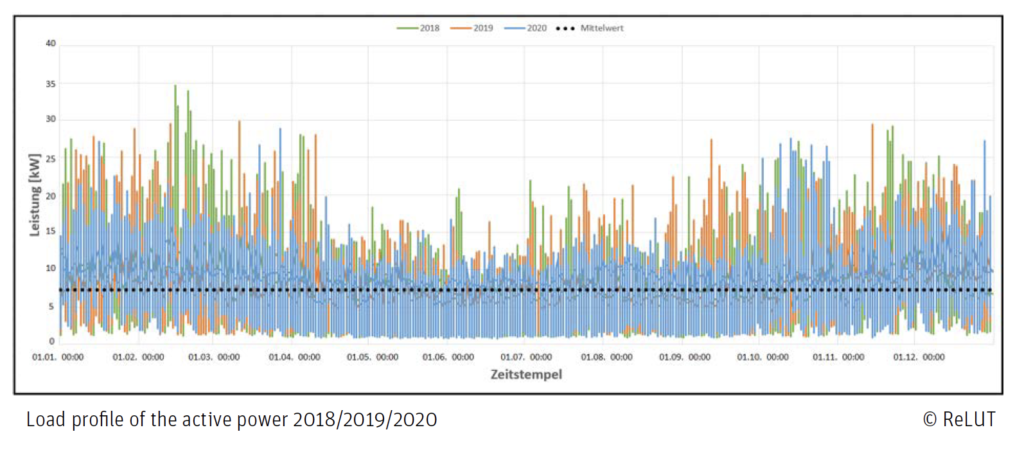

Using data that researchers from ReLUT – Research Lab for Urban Transport collected on the development of electromobility, we were able to plan a charging infrastructure for the project partner‘s use. The technical data (battery capacity, charging capability, and range) of various electric car models were collected to do so. The pool of electric cars described vehicles exclusively from the manufacturer Daimler as these vehicles represent the majority of vehicles at the project partner‘s site, which was initially considered. All vehicles can be charged with a Type 2 charging cable and charging power of up to 22 kW (AC). When analyzing the load profiles of 2018, 2019, and 2020 models to determine the available power at this location, the average power was about 7.3 kW, and the maximum power was approximately 34.62 kW.

On the procedural and logistical side, the consideration and theories of future electric mobility scenarios were backed up with concrete figures. The result is a tool that allows a wide range of variables to be selected and the parameters to be combined. The tool aims to determine both the total charging processes to be carried out and the total electricity consumption for the year for the scenarios in specific years to be selected.

Automotive logistics service providers then use these data to generate a benchmark for the fleet that passes through the logistics center each year, thus adapting logistics and charging structures to future electrification. The year 2020 shows the initial values of the simulations done.

Considering electrification ratios, fleet size, and a potential breakdown of e-car weight classes, the calculations result in a baseline of 4,700 charging operations for 2020 with an annual consumption of 17,000 kWh. This way, other scenarios and years can also be calculated and estimated. Looking at the best-case scenario for 2035, a significant increase to 21,500 charging processes and electrical consumption of 134,000 kWh can be seen. However, this assumes the optimal political steering of emission targets and the simultaneous implementation of the energy producing companies.