Over a third (34%) of global retail business leaders admit that the packages they ship worldwide are at least double the size of the actual product inside. This is leading to 46 bln US Dollar in extra cost of transportation. A global study by DS Smith has revealed this.

The Empty Space Economy

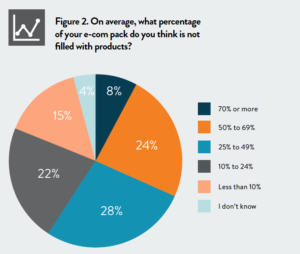

Shipping containers sailing across the oceans from Asia are 24% empty, according to research from DS Smith Consulting. This means that every year some 61 million 20-foot containers are shipped unnecessarily, costing tens of billions of dollars and emitting approximately 122 million tonnes of carbon dioxide into the atmosphere. That waste is further compounded once products make it to the shore and are sent from distribution centers to customers’ doors in e-com packaging. The recipients are often taken aback by the empty space in the packaging.

Despite the potential to significantly reduce shipping costs and CO2 emissions, cutting empty space in packaging is not a high priority for senior executives. Only 36% had conducted an audit of the empty space in their products’ packaging, and only a third (34%) had considered changing to a more optimised packaging solution.

Actions

Alessandro Fulvi, DS Smith Packaging Marketing Director, said: “Removing what is effectively ‘empty space’ would translate into billions of pounds worth of potential savings in shipping costs – which are currently passed onto the consumer. As the maturity of the e-commerce shopper evolves, it is no longer acceptable just to deliver goods on time and free from damage. Excess packaging and the empty space within a delivered carton frustrates the consumer and creates a negative brand experience”.

Alessandro Fulvi: “The key as with all things supply chain-related is to view the challenge holistically. There needs to be a greater focus on optimizing product packaging at the manufacturing source, and thereafter at a fulfillment center level. Firms can utilize new innovations such as DS Smith’s ‘Made2Fit’ which is an automated packaging system that eliminates void space and significantly reduces product movement that can lead to damage.”

Savings

Savings from cutting unnecessary costs due to empty space, which can amount to $46 billion globally, can be used to invest in innovative projects such as smart packaging and logistics initiatives. Budget increases for packaging initiatives, to be undertaken by 67% of companies over the next 12 months, can thus be recouped from such savings, according to DS Smith.